Silver Dollars & Trade Dollars of the United States - A Complete Encyclopedia

Q. David Bowers

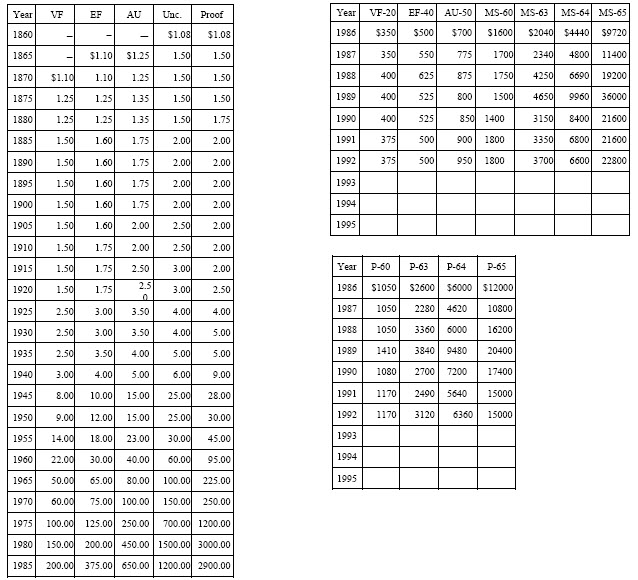

1860 Liberty Seated: Market Values

1860 Liberty Seated: Summary of Characteristics

Business Strikes:

Enabling legislation: Act of January 18, 1837 Designer of obverse: Robert Ball Hughes (after Gobrecht)

Designer of reverse: Robert Ball Hughes (after Reich)

Weight and composition: 412.5 grains; .900 silver, .100 copper

Melt-down (silver value) in year minted: $1.045 Dies prepared: Obverse: Unknown; Reverse: Unknown

Business strike mintage: 217,600; Delivery figures by day: March 3: 14,000; March 13: 12,000; March 14: 14,000; March 19: 12,000; March 26: 15,000; March 27: 5,000; March 30: 13,000; May 11: 20,000; May 25: 12,200;June 18: 14,000; September 27: 23,000; September 28: 13,000; October 26: 17,000; October 31: 4,000; November 5: 8,000; November 8: 5,000; November 19: 1,000; December 27: 15,400.

Estimated quantity melted: Unknown

Approximate population MS-65 or better: 10 to 20 (URS-5)

Approximate population MS-64: 20 to 40 (URS-6)

Approximate population MS-63: 20 to 40 (URS-6)

Approximate population MS-60 to 62: 40 to 75 (URS-7)

Approximate population VF-20 to AU-58: 500+ to 800 (URS-11)

Characteristics of striking: Usually well struck. Many higher grade coins show prooflike surfaces.

Known hoards of Mint State coins: None

Proofs:

Dies prepared: Obverse: At least 1; Reverse: At least 1.

Proof mintage: 1,330 minted; all delivered March 8, 1860; 527 distributed

Quantity melted: 803

Approximate population Proof-65 or better: 10+/- (URS-5)

Approximate population Proof-64: 32+/- (URS-6)

Approximate population Proof-63: 70+/- (URS-8)

Approximate population Proof-60 to 62: 160+/- (URS-9)

Commentary

Despite a large mintage, business strikes are rare; many were sent to China, where they were melted.

Additional Information

Snowden Describes the Minting Process

The following is from A Description of Ancient and Modern Coins in the Cabinet Collection at the Mint of the United States, by Mint Director James Ross Snowden, 1860, and describes the process of minting coins:

"The system of the present day, although much more multifarious in its details than the ancient process, requires no such army of employees; the whole force employed in the United States Mint, including officers, does not exceed 170.

"Bullion is brought to the mint in every form; amalgamations from the ore, coins, both foreign and domestic, bars, plate jewelry, etc., and these present many grades of quality, some being nearly pure; the remainder representing all the grades of fineness from that down to three thousandths. Some of it is perfectly ductile and easily worked, while a portion is brittle and requires to be toughened. A deposit of gold is often found to contain a large portion of silver which requires to be separated by chemical agents; all these facts are ascertained by the investigations of the Assay Department.

"The process is as follows: The deposit, upon being received, is weighed by the proper officers, and then sent to the deposit melting room, where the deposit is melted in a mass and cast into a bar; this bar is numbered, and a slip cut from it and sent to the assay department: here, by assaying this slip, the amount of pure metal contained in the entire deposit is ascertained. To do this with exactness requires a very careful and accurate manipulation. The operations of this department are intricate, and as they require an extended description for which we have not sufficient space, we are compelled to omit it and return again to the deposit. Its value having been ascertained by the assay, it is ready for the refining process.

"This is not strictly a Mint operation; in some countries these preliminary processes have to be performed by private refiners. But at the Mint of the United States, departments have been provided in which the silver is separated from the gold, the refining and standardizing of the metals, and casting them into ingots or small bars from which the coins are to be made, are performed. The bars or ingots thus produced are about 12 inches long, half an inch thick, and from one to two-and-a-half inches in width, according to the size of the coin for which they are intended. These bars, before being wrought, have to be assayed, in order to test their fineness, and those which are found to be either above or below the legal limits in fineness are returned to the melting room to be remelted and cast at the proper rate.